We’ve been asked a few questions about our design and manufacturing processes, so we thought we would tell you more about it…

At Adornment Archive we try to fuse traditional manufacturing techniques with modern technologies. The pieces in our Immortalising Welbeck collection have been created using a fusion of 3D modeling, 3D printing and lost-wax casting techniques, each piece in the collection is hand finished.

We model our jewellery in 3D.

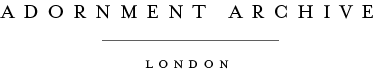

Then we send these 3D files to a specialised 3D printing facility to be printed in wax.

The wax prints are then fused onto a wax tree with other wax models, to maximize space.

A mould is then taken of the 3D wax prints using plaster. This mould has an entry and exit point which allows for the liquid wax to escape once the mould is heated to a high temperature inside a specialised oven. This mould has an entry and exit point which allows for the liquid wax to escape once the mould is heated to a high temperature inside a specialised oven.

Once the wax model has melted and the liquid wax has ran out of the mould the plaster will have hardened.

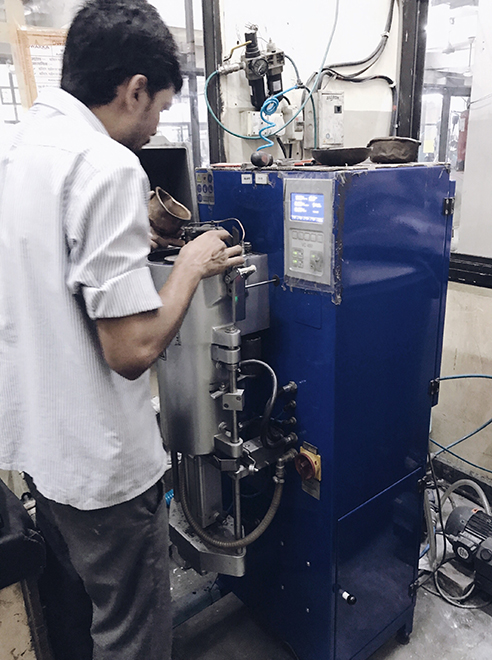

Molten silver is then injected into the cavity where the wax once was.

Once cooled the cast silver is removed from the moulds and polished by hand. This piece becomes the master piece.

A rubber mould is taken of the master silver jewellery piece. This mould is then used to produce many more wax jewellery pieces.

Steps 2-6 are then repeated but with the new wax pieces taken from the rubber mould.

See images for reference by all means get in touch with your questions!